Self Storage Facility Carlisle 01228 590397

Rome Street Depot

Shipping containers - the ubiquitous steel boxes that continually crisscross the globe delivering the majority of items we purchase (including what you are reading this article on now!), play a vital role in the global supply chain and have found new life in various industries.

From their construction to their growing role in the self-storage industry for businesses such as Storage Carlisle®, shipping containers’ versatility and durability have made them vital in running the world as we know it.

This article briefly delves into the process of actually making an ISO shipping container, their production hubs, the staggering number in existence, and their transformation into clever self-storage solutions, and follows with a brief scenario of "what if the shipping container wasn't invented!".

How a Shipping Container is Made

1. Design and Specifications

Shipping containers are engineered to strict standards to ensure they can withstand harsh environments and remain uniform for efficient stacking and transportation. The International Organization for Standardization (ISO) defines these specifications, including size, strength, and materials, ensuring interoperability worldwide. Standard container sizes include 20-foot and 40-foot lengths, with a width of 8 feet and varying heights of 8.5 or 9.5 feet (known as high-cube containers). This is why they are often referred to as ISO containers or ISO units.

2. Raw Material Preparation

The primary material for shipping containers is Corten steel, also known as weathering steel. Corten steel has a slightly different composition to normal steel, being an alloy of iron, carbon, chromium, nickel, copper, and phosphorous. Mild steel, also known as low-carbon steel, is primarily made of iron and carbon. This slight difference makes a big difference! The corrosion-resistant properties make it ideal for withstanding the harsh conditions at sea. Large steel rolls or plates are cut into sheets, which are then prepared for assembly. The durability of Corten steel also minimizes maintenance costs over the container’s lifespan.

3. Flooring and Frame Construction

The frame of the shipping container is the backbone of its structure, providing its strength and stability. The steel sheets are cut, welded, and bent to form the container’s walls, roof, and floor framework. Flooring, typically made of marine-grade plywood, is mounted onto steel cross-members for added durability and resistance to moisture. Some manufacturers also use bamboo as a sustainable alternative (see picture further down the page with the red coloured floor). Usually, in a 20 foot ISO shipping container (the most popular size we use), the floor is sufficient to hold around thirty tonne of contents!

4. Assembly and Welding

The panels and frame are welded together, forming the container’s body. Precision is critical to ensure airtightness and structural integrity. The corners of the container, known as corner castings, are reinforced to facilitate secure stacking and lifting by cranes in the docks. These corner castings feature universal fittings that allow seamless handling by standard equipment across the world. Hence, ISO.

5. Painting and Coating

To protect against rust and corrosion, the container is coated with layers of protective paint. The exterior typically receives multiple coats, including a primer, a base coat, and a final layer of weather-resistant paint. The paint finishes are really superb and tend to last the life of a shipping container used for self storage purposes. After painting, the application of logos, serial numbers, and identification markings required for shipping and tracking. On our storage facility you will see the serial numbers and these identification markings as the containers have travelled across the seas, then onto road by lorry, directly to our facility.

6. Quality Control and Testing

Every shipping container undergoes a rigorous testing procedure to ensure it meets ISO standards. These tests simulate conditions including heavy stacking of loads, extreme weather, and impact resistance. Some tests include pressure checks for airtightness and structural tests to withstand wind and waves. Only after passing these evaluations is the container certified for use. Although we don't require these certifications on our storage facility, you will see the certification "plates" which are an A4 size metal plate attached to the front of the unit stating when next inspection is due.

7. Final Assembly and Delivery

Once complete, the unit doors, locks, gaskets and seals are installed. The container is inspected for a final time, then transported to the ports, logistics hubs, or end-users such as ourselves around the world. Modern factories prioritize automation and efficiency, often producing thousands of containers per month. There are many different styles of container - some with multi doors, some with side doors etc. We generally use standard units with front opening doors.

Where Shipping Containers Are Made

The majority of shipping containers are manufactured in China, which dominates the global production market with an estimated 95% share. Key manufacturers include CIMC (China International Marine Containers), Dong Fang, and Singamas. This dominance stems from China’s efficient production capacity, cost advantages, and proximity to major shipping lines and ports.

Other countries, such as South Korea, Vietnam, and occasionally India, also contribute to container production but on a much smaller scale. Factories are typically located near steel production hubs and shipping ports to streamline the supply chain. The strategic positioning of these factories minimizes transportation costs for raw materials and completed units.

How Many Shipping Containers Are in Existence?

The exact number of shipping containers worldwide is challenging to correctly pinpoint due to constant production and decommissioning - containers don't last for ever. However, estimates suggest there are over 25 million shipping containers in circulation globally, with around 16 million in active use for transporting goods. Containers come in various sizes, with the standard 20-foot and 40-foot containers being the most common. Specialized containers, such as refrigerated units (reefers) and tank containers for liquids, add to this total.

Additionally, millions of containers have been retired from shipping by the shipping companies and repurposed for other uses, such as for use in self-storage, construction, and housing. We actually don't use these retired or used units as they are commonly called as we only use brand new ones.

The lifespan of a shipping container in active maritime service typically ranges from 10 to 15 years. During this time, containers endure extreme weather conditions, saltwater exposure, and heavy handling. Regular maintenance, such as repainting and repair, can extend their usability. A brand new shipping container on the other hand, used in a self storage environment lasts much longer, but in reality, we tend to replace them periodically once they begin to cosmetically degrade in order to maintain an attractive site.

Once containers are sold off by the shipping companies, they often find new life in terrestrial applications, where their robust construction can last another 20 years or more with proper care. The condition of a used container varies immensely but their versatility and resilience ensure they remain valuable assets even after their shipping days are over.

The ten minute You Tube video below shows how a shipping container is manufactured at the factory and manoeuvred at port, followed by a shorter three and a half minute video showing similar:

Why Shipping Containers Are Used for Self-Storage

Shipping containers’ robust design and uniformity have made them ideal candidates for self-storage applications. Here’s why they excel in this role:

1. Durability

Containers are built to withstand extreme weather, saltwater exposure, and rough handling. Their Corten steel construction ensures they remain secure and resistant to corrosion, making them perfect for long-term storage solutions. As brand new units, they are strong, clean and weatherproof, ensuring the protection of stored items either short or long term. They are attractive compared to a used unit - a new unit such as ours have varnished floors and a clean undented appearance.

2. Cost-Effectiveness

Compared to building traditional storage units, repurposing shipping containers is significantly cheaper. Their availability in large quantities and ease of modification make them a budget-friendly choice for storage operators and individuals. Containers can be purchased new or used, with used containers often being more affordable without compromising functionality.

3. Mobility

Shipping containers are inherently portable, designed to be easily moved by a Hiab truck or trains, and ships. This mobility allows some storage providers to deploy units off-site wherever demand arises, including remote or underserved areas. Portable self-storage solutions are becoming increasingly popular, as businesses can relocate units to follow customer needs or seasonal demand, though there is a cost factor to this.

4. Security

With sturdy steel walls, reinforced doors, and lockable mechanisms, containers provide excellent security. They can be further upgraded with high-security locks, alarms, and surveillance systems to deter theft. For self-storage operators, this level of security is a key selling point for customers seeking peace of mind.

5. Customising

Shipping containers are able to be customised easily. For self-storage purposes, they can be fitted with insulation, ventilation, and sometimes lighting to cater to a customers various storage needs. Doors can be modified for easier access, and partitions can create multiple storage units within a single container e.g.. a 20 foot container unit can be "divided" into two smaller units if they have doors at each end. Sometimes, they are used for industry, for example, to house generators in smaller container units.

6. Sustainability

Brand new containers often have bamboo flooring - though you can't tell the difference between wood and bamboo. The bamboo floors look amazing! Repurposing retired shipping containers aligns with sustainability goals, reducing waste and minimising the need for new construction materials. By giving old containers a new purpose, businesses contribute to recycling efforts and environmental conservation. This eco-friendly approach is increasingly appealing to environmentally conscious consumers.

7. Versatility in Storage Applications

Shipping containers can accommodate a wide range of storage needs, including:

Residential Use: Homeowners use containers to store furniture, seasonal items, or tools during renovations or relocations.

Commercial Use: Businesses need to store stock, inventory, equipment and documents in secure container units at low cost.

Specialised Storage: Containers are modified to hold temperature-sensitive goods, hazardous materials, or oversized items.

Additional Benefits of Using Shipping Containers in Self-Storage Facilities

1. Scalability

Self-storage operators can easily scale their facilities by adding or removing containers based on demand. This is cost saving. This modular approach eliminates the need for extensive construction projects, allowing businesses to adapt quickly to market changes. The ease of adding new units makes containers an excellent choice for facilities in growing urban or suburban areas.

2. Low Maintenance

Shipping containers are designed to endure harsh conditions with minimal upkeep. Their weather-resistant construction means they require less maintenance compared to traditional storage units, reducing operational costs for facility owners. Regular inspections and minor repairs are usually sufficient to keep the containers in excellent condition, though less so with brand new units such as the types we use on our facility.

3. Space Efficiency

The standardized ISO dimensions of shipping containers make them easy to organise and stack - up to around eight units high, maximizing the use of available land. Facilities with limited space can benefit from stacking containers vertically, creating multi-level storage solutions. This efficient use of space is particularly valuable in urban areas where land is at a premium.

4. Rapid Deployment

Operating a self-storage facility such as Storage Carlisle® is significantly faster than constructing traditional buildings. Containers can be delivered, modified, and ready for use within weeks. This rapid deployment capability is ideal for meeting sudden surges in storage demand, such as during the housing boom through 2020 to 2024 or peak moving seasons.

5. Flexibility in Location

Shipping containers can be easily relocated, making them suitable for temporary storage needs or facilities in transitional areas. This flexibility enables operators to serve customers in dynamic markets, such as construction sites or disaster relief zones. Portable storage units also offer a competitive advantage by reaching customers who require on-site storage solutions.

6. Climate Resilience

The weatherproof design of shipping containers ensures stored items are protected from extreme temperatures, rain, snow, and wind. For areas prone to natural disasters, containers can provide a reliable storage solution that resists damage from severe weather events. Their sturdy construction minimizes the risk of leaks, dents, or structural compromises, giving both operators and customers confidence in their durability.

7. Customer Appeal

Modern consumers are increasingly drawn to storage solutions that offer security, affordability, and convenience. Shipping container-based storage units meet these criteria and are perceived as reliable and innovative. By offering a wide range of different sizes of units i.e.. 8, 10, 20 foot ones results in additional levels of affordability. Look at the row of containers in the picture below and see how convenient these ones are to use at our Carlisle depot.

By combining durability, flexibility, and eco-friendliness, shipping containers have redefined the landscape of the self-storage industry, making them an indispensable resource for businesses and individuals alike.

Photo above: Interior of a shipping container with bamboo floor - yes, it looks and performs amazing capable of holding thirty tonne.

Why Shipping Container Storage is Superior to Traditional Building Storage.

Shipping container storage is quickly becoming the go-to solution for modern storage needs, and it’s no wonder why. Like we have discussed above, these sturdy steel units offer a range of advantages over traditional building storage that appeal to those moving home, businesses, individuals, and industries alike. Let’s dive into the many reasons why shipping containers are a better choice for storage, touching on aspects like cost, durability, flexibility, and even their environmental impact.

1. Cost-Effectiveness

When it comes to affordability, shipping container storage stands out as a clear winner. Constructing a traditional storage facility requires a hefty investment in land, materials, and labour. Shipping containers, by contrast, are pre-built and ready to use, making them much more budget-friendly. We can pass these savings on to you, the customer, and the savings are often huge compared to "in building" storage.

Lower Initial Investment: Although facilities such as hours run into the hundreds of thousands of pounds, they are still cheaper than the cost of building a permanent storage facility, yet still provide excellent performance. Cost savings can be passed on to you.

Minimal Maintenance Costs: Traditional buildings require constant upkeep—roof repairs, painting, pest control—the list goes on. These all cost money and would need factored into customer pricing. Shipping containers, built to weather harsh conditions, require far less maintenance. A little rust prevention and occasional cleaning are often all that’s needed on hinges and door mechanisms to keep them in perfect operational order while saving you money at the same time.

2. Unmatched Durability

Shipping containers are designed to withstand the harshest environments, from stormy seas to blazing sun. Their resilience makes them ideal for storage, especially in challenging climates.

Weatherproof and Secure: Made from Corten steel, these containers resist rust, corrosion, and extreme weather. Rain, snow, or intense heat won’t compromise the safety of the items stored inside.

Built Tough: Unlike many traditional storage buildings that might degrade over time, shipping containers can endure heavy impacts and rough handling without losing structural integrity. They are designed to be transported around the world for an average of 10 to 15 years, after all! This makes our brand new ones even more suitable for our type of self storage facility.

Whether you’re storing an entire house full of contents during a house removal or relocation, tools, furniture, or sensitive documents, a shipping container offers unbeatable protection against the elements and usual wear and tear.

3. Flexibility and Mobility

Traditional building storage is fixed—once it’s built, it’s not going anywhere. Shipping containers, on the other hand, are designed for mobility and adaptability.

Easy to Move: Need your storage closer to a work site or event? Shipping containers can be transported via Hiab. Often, here at Storage Carlisle® , for overseas removals, specialist firms can deliver contents of an entire house directly on to our site in a ISO shipping container.

4. Rapid Reactions!

Immediate Availability: Containers can be delivered to our site and put to use the same day in the event of emergency storage.

5. Eco-Friendly and Sustainable

In an era where sustainability is increasingly important, shipping container storage is an eco-conscious choice.

Minimal Environmental Impact: Unlike traditional buildings, which often require excavation and significant site preparation, shipping containers can be placed with minimal disruption to the land. They’re a low-impact solution that aligns with green business practices.

For those who value sustainability, choosing containers is an easy way to make a positive environmental impact while meeting practical storage needs.

6. Enhanced Security

Security is always a concern when it comes to storage, and shipping containers excel in keeping your items safe.

Solid Steel Construction: The sturdy steel walls of a shipping container are far tougher than the materials used in many traditional storage units. They provide excellent resistance against break-ins.

Customisable for Extra Security: You can easily add features like heavy-duty locks, alarm systems, and security cameras to further protect your belongings.

Whether you’re storing valuable equipment or sentimental items, shipping containers provide peace of mind that traditional buildings may struggle to match.

7. Versatile and Customisable

Shipping containers are incredibly versatile, making them suitable for a wide range of storage needs.

Adaptable Design: Need shelves? Partioning? Containers can be modified to suit specific requirements. For example, adding power to them, while adding partitions and racking can create multiple storage areas within one container.

Traditional storage buildings often lack this level of customisation, giving containers a significant edge!

8. Time Saving and Storage Efficiency

One of the lesser-discussed benefits of shipping containers is their efficient time saving benefits!

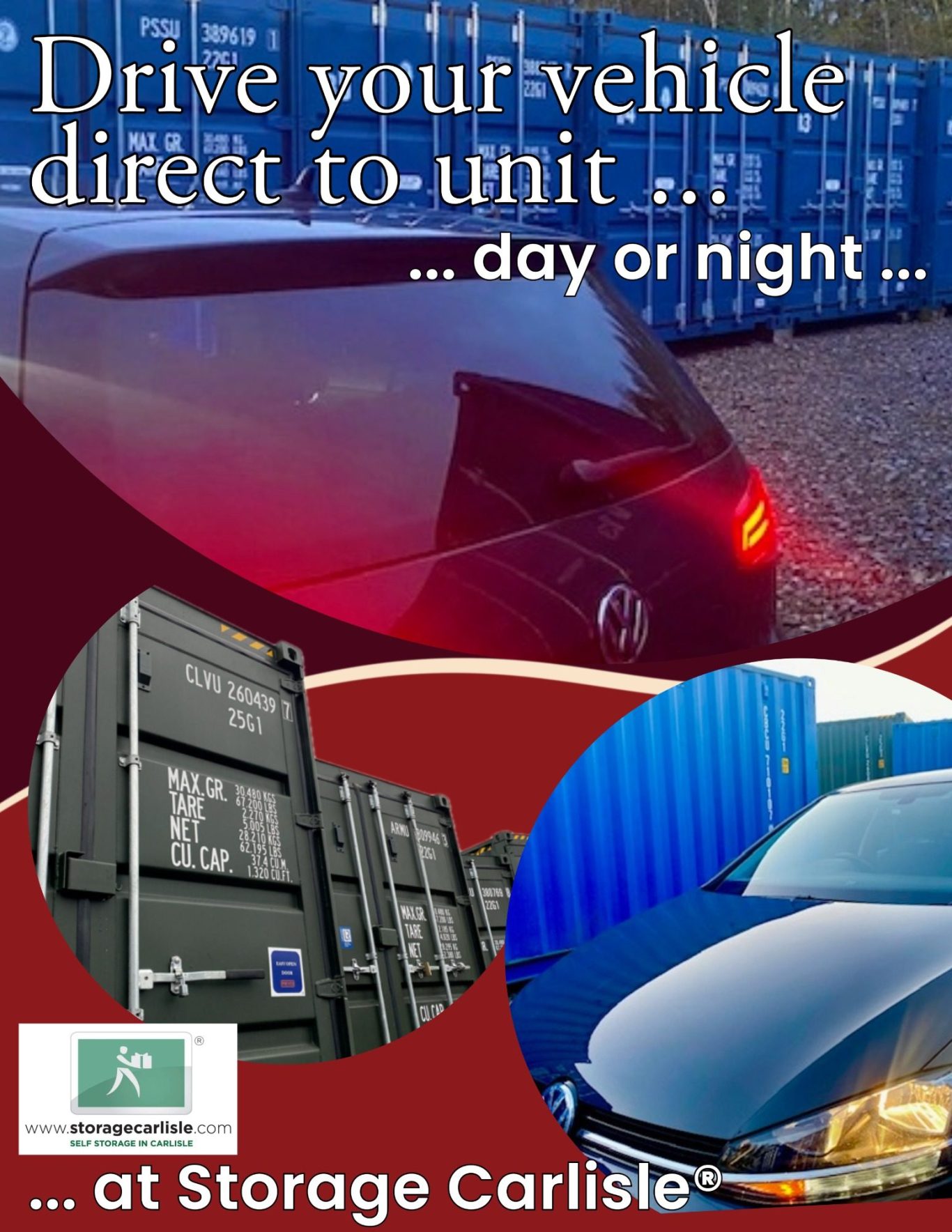

Ground floor access: Our container storage units are positioned on ground floor level meaning there are no staircases or lifts to negotiate. Driving directly up to your storage unit is a massive time saving advantage.

Standardised Dimensions: The uniform shape of containers makes them easy to arrange and optimise within a storage facility. Afterall, they are fixed dimensions. Unlike traditional buildings, which might have irregular layouts, containers maximise every inch of available space.

This time saving quality results in a superior customer experience when using our facilities here in Cumbria.

Conclusion

When it comes to storage solutions, shipping containers offer unbeatable advantages over traditional building storage. They’re cost-effective, durable, and flexible, with the added benefits of quick deployment, enhanced security, and environmental sustainability. All these cost savings passed on to YOU the customer!

As the demand for quality and reliable storage grows on our facility, shipping containers will remain a top choice. For those seeking a practical, modern storage solution, our units fit the bill completely!

First though, this quick four and a half minute video explains a bit how global containerisation works:

We've discussed in length all the benefits of shipping containers. But just for a moment Imagine a world where the shipping container didn’t exist. It didn't until the 1950s. It might seem hard to picture today, especially since shipping containers are so common. But it hadn’t been invented, things would look pretty different. The way we trade, shop, and even live would be drastically different. Here’s how the world might look without shipping containers.

1. Trade Would Be Slow and Expensive

Before containers, shipping goods across the world was a real hassle. Everything had to be loaded by hand - yes, by hand— bags, barrels, crates, you name it, all by hand. This took a ton of time and labour, making international trade slow and costly. If containers had never come about, we’d still be dealing with this old-school system. Can Can you Imagine the delays and mistakes that could happen when goods are manually unloaded one by one? We dread to think. Prices for products would be higher, and businesses would find it way more expensive to get goods from one country to another.

2. A Smaller, Less Connected World

The shipping container made the world a lot more connected. It made it possible for companies to send goods across oceans easily, allowing businesses to source materials from all over the globe. Now this may be a sore point, but without the container, countries wouldn’t trade as much. Global supply chains, the backbone of everything from tech gadgets to clothes, wouldn’t be what they are today. In fact, globalisation itself would probably be much slower to develop. Countries like China or India might not have seen the same rapid growth that they did in recent decades, and poorer regions might have stayed isolated.

3. Ports Would Look Very Different

Think of the giant ports we see today—huge, efficient, and full of massive container ships unloading thousands of containers at a time. Without containers, ports would be a lot smaller and a lot slower. Instead of unloading one giant container ship in a few hours, they’d still be unloading individual crates and barrels by hand. Port cities wouldn’t have grown the way they did, either. Without the shipping container, there wouldn’t have been the need for these massive, highly automated facilities, and cities near the water wouldn’t have developed into the global trade hubs they are today. Is that a good or bad idea! We don't know, but the world would be vastly different to how it is now.

4. Supply Chains Would Be a Nightmare

Today, global supply chains are like a well-oiled machine. Companies can get what they need from almost anywhere in the world because it’s easy to ship goods in standardized containers. But if containers didn’t exist, getting products from different countries would be a lot more complicated. Manufacturers would have to rely on local suppliers instead of sourcing materials from halfway across the globe. This would make things more expensive and less efficient. The world wouldn’t be able to access as many affordable goods, and it would be harder for companies to scale.

5. The Environment Might Be Affected Differently

It’s interesting to think about how the environment might change in a world without containers. On one hand, modern container ships are huge and burn a lot of fuel. But on the other hand, they’re incredibly efficient in terms of carrying a lot of goods at once. Without containers, ships would probably be smaller and less fuel-efficient, but trade would be slower and on a smaller scale. So, there might be less overall transportation, which could lower emissions. But it’s a toss-up—fewer goods would be traded, but they’d still be less efficient to move.

6. Innovation in Shipping Would Be Much Slower

The shipping container did more than just change how we move things—it sparked a lot of other innovations. Things like container ships, automated cranes, and logistics technologies wouldn’t exist in the same way without containers. E-commerce, fast fashion, and just-in-time manufacturing grew because of the ease of getting products from anywhere at a lower cost. Without the container, all of this would have developed much more slowly, or not at all. The world’s supply chain would have been a lot more disjointed, and businesses wouldn’t have the same global reach they do today.

7. Jobs and Work Would Be Very Different

Shipping containers also changed the job market, especially in ports and shipping. The labour-intensive jobs of the past have been replaced by more automated processes. Big cranes unload containers quickly, and machines help move them around. Without containers, we’d still be relying on lots of manual labour at ports. So while there would still be jobs, they’d look very different. It’s possible that automation would have taken longer to catch on, and workers might still be unloading goods by hand in the 21st century.

The shipping container is one of those inventions that’s so ubiquitous now that we don’t always stop to think about how much it changed the world. Without it, global trade would be slower, more expensive, and less efficient. The world would be less connected, and economies wouldn’t have grown at the same pace. Ports would be smaller and more labour-intensive, and the goods we buy every day would be pricier and harder to get. Simply put, the shipping container has been one of the main drivers of the global economy as we know it today. Without it, our world would look much less connected and much slower.

Well, that's just an opinion. The fact is, the shipping container has revolutionised the world today. If they hadn't been invented, would Storage Carlisle® be here today? That's the question.

Storage Carlisle® is a long established storage facility based in Carlisle, Cumbria, England. They use new ISO shipping containers on their extensive self storage facilities for virtually any type of storage - be it domestic or business related storage from a single box to an entire house full.

All rights reserved. Hansford Ltd. STORAGE CARLISLE ® SELF STORAGE & SHIPPING CONTAINER STORAGE. 24 hour access, low cost self storage services | Carlisle City Centre. "Storage Carlisle", "Your Lock Your Key" & the Storage Carlisle logo are registered trademarks. This website and all photographs are copyright, owned exclusively by Storage Carlisle® or under licence. Telephone 07739 103165. Storage Carlisle, Rome Street Depot, Carlisle.

Self storage Carlisle | Furniture Storage | Shipping container storage, Removals, Household, furniture, business, car park, vehicle, caravan and Storage in Carlisle, Cumbria | Railway luggage and Station baggage service | Student storage and document storage solutions | Locations: CA1, CA2, CA3, CA4, CA5, CA6, CA7, CA8, CA9, CA10, CA11, CA12, CA13, CA14, CA15, CA16, CA17, CA18, CA19, CA20 | Yards & industrial / commercial property | Work space | Work shops, industrial and business units. Rome Street Depot, Carlisle, CA2 5AQ.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.